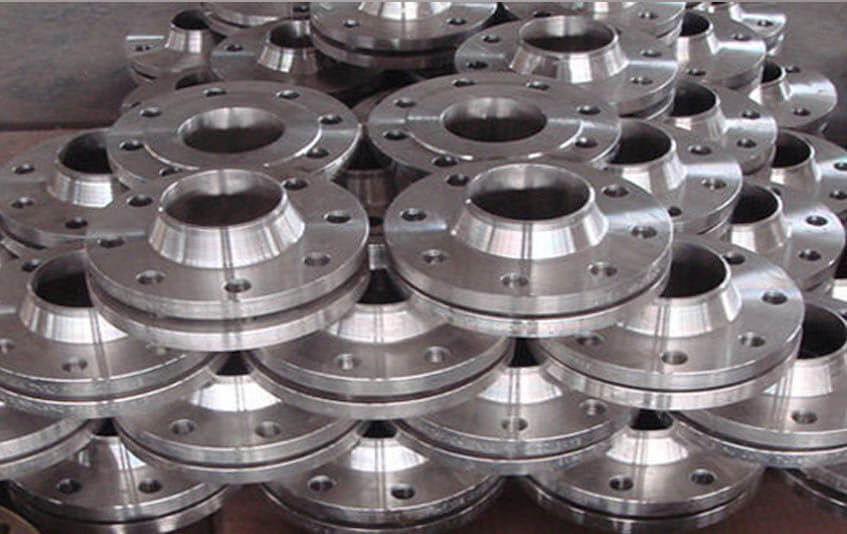

SMO 254 flanges are high-performance super austenitic stainless steel flanges known for their exceptional resistance to corrosion, pitting, and crevice attack. Manufactured from UNS S31254 alloy, these flanges offer high strength along with excellent performance in chloride-rich and aggressive environments. SMO 254 flanges are widely used in applications requiring superior durability, reliability, and resistance to harsh chemicals, making them suitable for industries such as chemical processing, offshore oil & gas, desalination, pulp & paper, and power generation. Their ability to withstand extreme service conditions ensures long-term efficiency and reduced maintenance in critical piping systems.

SMO 254 flanges are premium-grade super austenitic stainless steel flanges manufactured from UNS S31254 alloy, offering outstanding corrosion resistance and high mechanical strength. These flanges are specially designed to perform in aggressive environments containing chlorides, acids, and seawater. With excellent resistance to pitting, crevice corrosion, and stress corrosion cracking, SMO 254 flanges are widely used in demanding applications across chemical processing, offshore oil & gas, desalination, pulp & paper, and power generation industries. Their reliability and long service life make them a preferred choice for critical piping systems.

Product Overview:-

Ganpat Metal Industries is a fulfilled Manufacturers, Stockists, and Suppliers of a superb quality degree of SMO 254 Flanges. These SMO 254 Flanges have extraordinary association to pipes and have a long life in the refining business for low to high-pressure applications. We make these SMO 254 Flanges according to individuals overall and overall quality principles. SMO 254 Flanges contain more prominent extents of chromium regarding different prepares and along these lines have unprecedented use obstruction. SMO 254 Slip-on Flanges contain around 10% of chromium.

Grade SMO 254 Long Weld Neck Flanges are thermally steady and have moderate strength notwithstanding, when the temperature is high. SMO 254 Threaded Flanges whose plan draws in joining moreover made protection from pitting, high strength, stress crumbling, hole use, and breaking. SMO 254 Flanges is gathered in austenitic treated steel with a Molybdenum content something like 6%, to that end this Alloy is similarly called 6Mo and was made plans for use in seawater and chloride conditions.

Specification:-

Specification of SMO 254 Flange

| Range | : | 1/2”~60” |

| Specification | : | ASTM A812 / ASME SA812 |

| Dimensions | : | ANSI/ASME B16.5, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Standards | : | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Class/Pressure | : | 150#, 300#, 600#, 900#, 1500#, 2500# | PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Face Type | : | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

Benefits:-

With high versatility and effect strength, SMO 254 is a more reasonable decision rather than high nickel blends and titanium Alloys in unambiguous applications. We have fundamentally found out about get-together SMO 254 Flanges and other line fittings. Our 254 SMO Flanges are made utilizing quality material and go through a cautious quality check at all times of creation to guarantee quality. Organized in consistence with generally speaking quality guidelines.

Conclusion:-

SMO 254 flanges provide an ideal solution for piping systems operating in highly corrosive and demanding environments. Their superior resistance to pitting, crevice corrosion, and stress corrosion cracking, combined with high strength and excellent fabrication properties, ensures reliable and long-term performance. Widely used in critical industries such as chemical processing, offshore oil & gas, desalination, and power generation, SMO 254 flanges help reduce maintenance requirements and enhance operational efficiency, making them a dependable choice for high-performance industrial applications

Email Id:-[email protected]

Contact Number:-22-2389-3333